DAMANUS MB. | FASTENER SUPPLIER

0,38 € – 130,28 €Price range: 0,38 € through 130,28 €

CHOOSE FROM

*The quantity to be selected is the number of boxes.

**FREE SHIPPING from 1000 Eur.

info@damanus.lt

Send an enquiry to find out more details

Applications

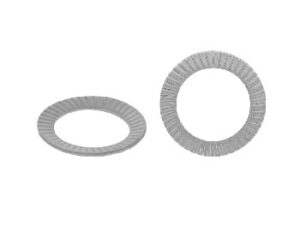

Conical spring washers are primarily used to maintain tension in bolted connections, ensuring stability and preventing loosening caused by vibrations or thermal expansion. They are especially effective in assemblies requiring high clamping forces or where components are subject to dynamic loads. Additionally, they help distribute loads evenly, reducing material deformation and improving the reliability of mechanical systems.

Fields of Use

These washers are widely applied in industries such as machinery construction, automotive, aerospace, metal fabrication, and heavy equipment. They are also suitable for electrical assemblies and environments with space constraints or exposure to corrosive elements.

Characteristics

Conical spring washers are designed to provide consistent tension and absorb vibrations. They are typically made from materials like stainless steel or other corrosion-resistant alloys, making them durable and suitable for harsh environments. Their unique conical shape allows them to compensate for thermal expansion and maintain preload under varying conditions.

| Weight | N/A |

|---|---|

| Selected product | similar to DIN 6796 A2 10, similar to DIN 6796 A2 12, similar to DIN 6796 A2 14, similar to DIN 6796 A2 16, similar to DIN 6796 A2 18, similar to DIN 6796 A2 20, similar to DIN 6796 A2 22, similar to DIN 6796 A2 24, similar to DIN 6796 A2 3, similar to DIN 6796 A2 4, similar to DIN 6796 A2 5, similar to DIN 6796 A2 6, similar to DIN 6796 A2 8, similar to DIN 6796 A4 10, similar to DIN 6796 A4 12, similar to DIN 6796 A4 14, similar to DIN 6796 A4 16, similar to DIN 6796 A4 18, similar to DIN 6796 A4 20, similar to DIN 6796 A4 22, similar to DIN 6796 A4 24, similar to DIN 6796 A4 3, similar to DIN 6796 A4 4, similar to DIN 6796 A4 5, similar to DIN 6796 A4 6, similar to DIN 6796 A4 8 |